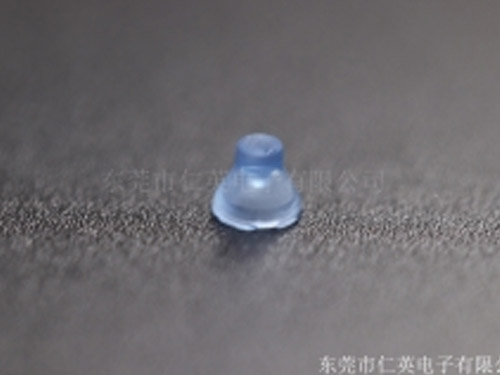

One: Reasons for impurities and black spots on the surface of the silicone tube:

1: Raw materials cause badness. 20% of the reason for the black spots of the silicone tube/strip in the production process is from the black spot impurities in the raw materials.

2: The secondary rubber mixing leads to excessive black spots. Generally, the vulcanizing agent becomes invalid after long-term storage of the mixed rubber. At this time, it is necessary to re-mix and add the vulcanizing agent. Black spots and impurities may also appear in the secondary rubber compound.

3: Caused by the forming operation. In the production process, the exhaust stroke of the machine is too large, and black spots may be inhaled during exhaust.

Two: How to deal with impurities and black spots on the surface of the silicone tube:

1: It is necessary to carefully inspect the product to see if there are black spots and impurities before mixing the rubber.

2: During the secondary rubber mixing process, there may be rubber contamination from the hands, the vulcanizing agent and the air, resulting in black spots and impurities in the molded and vulcanized product.

3: During the molding operation, the environment around the machine and the indoor environment need to be strictly controlled. There are too many debris on the mold, and don’t pay attention to it. It appears on the new online mold. There are more debris phenomena, so the general silicone product processing manufacturers will first sandblast the mold or spray Teflon to clean the mold, which can solve the key black spots; pay attention to the process of weighing materials Clean your hands and clean up all items that may cause black spots and impurities on the work surface and the surrounding area. Man-made phenomena are an important factor in the appearance of bad appearance. Therefore, it is necessary to organize and rectify yourself to develop good operating habits to prevent appearance black spots. unpleasant sight!

Product impurity black spots are a common problem of silicone tubes/strips. Once there are black spots, the entire tube will be scrapped. This is another headache for many silicone products factories. In addition to the silicone tube, the black spot impurities in other silicone products are also difficult to control. Therefore, the black spot impurities need to be controlled in its source material. Chaote New Material is an organic silicone manufacturer with 12 years of application experience. Aiming at this problem, we have developed an extruded silica gel raw material that can control 98% of impurity black spots, which has helped many manufacturers to solve this problem.

At the same time, pay attention to the following points: handle the dirt and impurities of the product while mixing the rubber, the hands of the operator mixing the rubber, the tools in contact with the rubber, the production machine Keep the table clean, keep the extrusion line clean and so on.